There are three main requirements for starting a shiitake mushroom business:

1. At least 3 ½ acres of vacant land for buildings that will hold and grow the mushrooms indoors. The more mushrooms you want to produce, the more land you will need.

2. Advanced growing techniques and efficient automated equipment that we will provide.

3. The market that you will sell all your products to. The more mushrooms you can sell, the more land you will need.

To start up a shiitake mushroom business, you will need a machine system, a sterilization system, growing buildings and other accessories. All of them working together will form an efficient specialty mushroom growing business.

Machine System

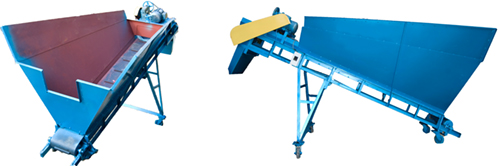

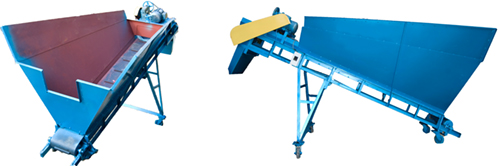

The machine system includes the bagging machine, mixer, storage conveyor, conveyor, plastic baskets, plastic bags, and necks.

The bagging machine makes 1200 –1600 bags per hour (20-26 bags per minute). The bag weighs 3-3 ½ lbs. (1.36kg - 1.58kg), and can be inoculated with a variety of mushroom spawn so you can grow different mushrooms by using the same machine system.

The mixer can mix 350-400 lbs (160kg - 180kg) of dry sawdust per cycle.

The storage conveyor can hold 750-850 lbs. (340kg - 385kg) of mixed sawdust, and transfers the sawdust to the bagging machine continuously. At the same time, the mixer is able to continuously transfer mixed sawdust to the storage conveyor. Working together, the whole system can make thousands of mushroom bags without any stops.

After the machine fills the bags, put on a neck on the top of the bag and place it into the plastic basket where all of the bags will stay until the mushrooms are done growing. Each basket will hold 12 bags for easy transportation.

Accessories:

Accessories include plastic bags, baskets and rings. These items are specifically made for our machine system.

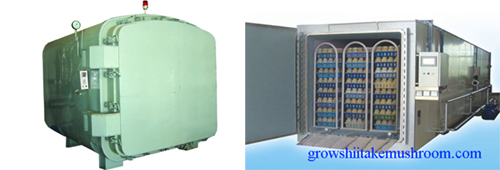

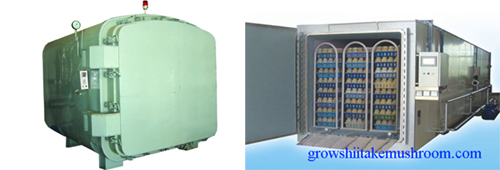

Sterilization system

The sterilization system includes the boiler, autoclave, and cooking cart. Depending on your company’s size, you can choose different sized autoclaves that will sterilize 2000-5000 bags each time.

There are two methods for sterilizing the mushroom substrate: high pressure and low pressure sterilization. Each one has its own pros and cons and you can choose the one that best fits your company’s needs.

High pressure sterilization

The pressure inside the autoclave can reach 20-30 PSI. An increase in the water’s boiling point follows the pressure increase, so the temperature in the autoclave can reach over 120 C (250 F), allowing the high-pressured hot steam to have more penetrating power to kill all microbes in a very short time. In the mushroom and food industries, temperatures over 121 C (250 F) will disintegrate and carbonize some nutritious ingredients. In practice, the high-pressure sterilization temperature will not exceed 121C (250 F). In the mushroom field, the temperature range of the steam is between 110 C to 121 C (230 F to 250 F), which will eliminate all microbial life, include bacteria, fungi, spores, etc. in the mushroom substrate in 3-5 hours.

Pros: Short sterilization time. Good for large-scale companies.

Cons: High start up and energy cost.

Low pressure sterilization

The pressure in the autoclave is a little above the atmospheric pressure, and the temperature only reaches 98-102 C (212 - 220 F). Keep this temperature for a few hours to sterilize the mushroom bag.

Since there is very low pressure on the boiler and autoclave, it is much easier for factories to manufacture this equipment, so the cost is much lower than the high-pressure equipment.

Pros: Lower cost and less maintenance requirement. It is good for most shiitake mushroom companies that will produce less than five tons of mushrooms per day.

Cons: Longer sterilization time.

Home made sterilization system

The sterilization process is just like how we cook our daily food. The autoclave holds the steam and mushroom bags, and the boiler provides the steam that sterilizes the mushroom substrate.

Based on our experience working in commercial shiitake mushroom companies, we have designed and helped our customers build a very efficient homemade sterilization system that only costs about $2,000 and can hold 3000-5000 mushroom bags each time.

If you want to start a small to medium-sized shiitake mushroom business that will produce a few thousand to over ten thousand pounds of mushrooms per month, for about $28,000-$45,000 you can get part of or all of the machine system and some accessories to go with the home made sterilization system. That is equivalent to what it costs other shiitake growers to buy the boiler and autoclave alone. If you have some kind of vacant building (commercial building, barns, chicken houses, etc…) you can start to grow your own shiitake mushrooms right away.

Pros: Very low cost to start a shiitake mushroom business. It is good for companies that produce less 10,000 lbs of shiitake mushroom per month.

Cons: Longer sterilization time.

Building System

Many kinds of buildings can be used for grow shiitake and oyster mushrooms. For example, commercial buildings, big barns, old chicken or pig houses and horticultural greenhouses work well. Depending on your local weather conditions, you can also build different kinds of buildings to hold the mushrooms indoors.

There is no standard building for a mushroom business, but there is one that is much cheaper and easier to build than other kind of building and fits most areas. It is an arch-like building.

The building’s frames are made by metal pipes and covered with two layers of plastic film and suitable insulation that meets your local building codes.

Its size is about 28 ft wide X 96 ft long X 14 ft high (8.50 m X 30m X 4.30m). It has about 2600 SF (255-sq. m).

Each building will hold 40,000—50,000 incubating bags. During fruiting time, it can hold 13,500-14,500 oyster bags or 20,000 to 35,000 shiitake bags.

The building is insulated with insulation that meets your local building codes, and is equipped with HVAC (Heating, Ventilation and Air Condition) system. It is suitable for most areas.